most popular products

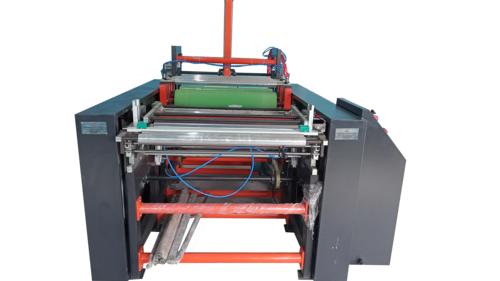

दस à¤à¤¤à¥à¤ªà¤¾à¤¦à¥à¤ à¤à¥ साथ पà¥à¤ªà¤° रà¥à¤² बनानॠà¤à¥ मशà¥à¤¨ à¤à¥à¤®à¥à¤¬à¥

Price 500000 आईएनआर/ Unit

MOQ : 1 Unit

दस à¤à¤¤à¥à¤ªà¤¾à¤¦à¥à¤ à¤à¥ साथ पà¥à¤ªà¤° रà¥à¤² बनानॠà¤à¥ मशà¥à¤¨ à¤à¥à¤®à¥à¤¬à¥ Specification

- ग्रेड

- टाइप करें

- मटेरियल

- Mild steel, Stainless steel contact parts

- क्षमता

- 600-900 rolls/hour

- कम्प्यूटरीकृत

- कंट्रोल सिस्टम

- कटिंग स्पीड

- 180-200 cuts/min

- काटने का आकार

- Adjustable from 50 mm to 450 mm

- काटने की मोटाई

- 0.6 mm to 6 mm

- वोल्टेज

- 220 V / 380 V

- पावर

- 4 kW

- वजन (किग्रा)

- 1600 kg

- आयाम (एल* डब्ल्यू* एच)

- 12 ft x 7 ft x 6 ft

- रंग

- Blue & Silver

- Tension Control

- Auto tension control for precise winding

- Suitable Raw Materials

- Virgin and recycled jumbo tissue rolls

- Servo Motor

- Integrated high-precision servo drive

- Paper GSM Range

- 13 gsm to 40 gsm

- Paper Loading

- Hydraulic loading system

- Compressed Air Required

- 5-6 bar

- Noise Level

- ≤80 db(A)

- Safety Features

- Emergency stop button, overload protection system

- Max Roll Diameter

- 180 mm

- Embossing System

- Steel to Rubber/Steel to Woolen optional

- Frequency

- 50/60 Hz

- Operator Requirement

- 1-2 persons

- Working Environment Temperature

- 5°C to 40°C

- Machine Combo Includes

- Toilet roll, kitchen roll, maxi roll, embossing machine, band saw cutter, slitting machine, rewinder, core making unit, packaging unit, counting unit

About दस à¤à¤¤à¥à¤ªà¤¾à¤¦à¥à¤ à¤à¥ साथ पà¥à¤ªà¤° रà¥à¤² बनानॠà¤à¥ मशà¥à¤¨ à¤à¥à¤®à¥à¤¬à¥

FTC paper roll making COMBO machine10 products manufactured in single machine

Toilet roll

Kitchen towel roll

HRT roll/ maxi roll

JRT roll

Hospital paper bed roll

Thermal paper roll

Thermal paper roll printed

Dining table paper roll

Aluminium foil roll

Baking paper roll

All rolls making in single machine

Comprehensive Combo for Tissue Production

This machine combo is expertly crafted to manufacture a variety of paper rolls, including toilet, kitchen, and maxi rolls. Featuring ten integrated units such as embossing and core making, it streamlines production from start to finish. Its automatic operation reduces manpower and maximizes efficiency in industrial environments.

Precision Engineering and User-Friendly Controls

Equipped with a PLC touch screen, integrated servo motor, and auto tension control, our machine ensures accuracy in size, cut, and roll quality. The hydraulic loading system simplifies material handling, while adjustable cutting sizes make it versatile for varied product requirements.

Safety, Reliability, and High Output

The machine supports safe operation with emergency stop features and overload protection. It maintains a quiet working environment and can produce 600-900 rolls per hour. Perfect for manufacturers, distributors, and suppliers seeking robust production capabilities in India.

FAQ's of Paper roll making machine combo with ten products:

Q: How does the Paper Roll Making Machine Combo operate and what products can it produce?

A: The combo integrates ten units-including embossing, slitting, rewinder, and packaging-to fully automate the process of producing various paper rolls such as toilet, kitchen, and maxi rolls. It can handle both virgin and recycled jumbo tissue rolls and delivers consistent, high-quality output.Q: What are the main benefits of using this machine combo for commercial tissue production?

A: The machine offers high-speed, efficient production (600-900 rolls/hour) with minimal operator effort, automated loading, and precise paper tension control. It provides versatile cutting sizes and thickness, which suits diverse client requirements, and integrates robust safety features for secure operation.Q: When should the machine be maintained, and what is the recommended operator requirement?

A: Routine maintenance should align with your production schedule and manufacturer guidance to ensure peak performance. Only 1-2 trained operators are generally needed due to the system's high degree of automation and intuitive PLC touch screen controls.Q: Where is this Paper Roll Making Machine Combo best suited for use?

A: This machine is ideal for industrial settings like tissue product manufacturing units, supply hubs, and distribution centers across India, particularly where high-output, diverse paper roll production is required.Q: What raw materials and paper specifications does the machine support?

A: The combo is compatible with both virgin and recycled jumbo tissue rolls. It accommodates a paper GSM range of 13 to 40 gsm and supports roll diameters up to 180 mm, delivering broad manufacturing flexibility.Q: How does the machine ensure product precision and consistent quality?

A: Advanced features such as high-precision servo drives, PLC touch screen controls, and automatic tension management deliver consistent, accurate roll sizes and cuts, ensuring product quality meets industry standards every cycle.Q: What safety and environmental features are included in the machine?

A: The machinery is equipped with an emergency stop button, overload protection, and operates at less than 80 db(A), supporting a safe and low-noise work environment within a 5C to 40C temperature range.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Paper Roll Making Machine Category

डाइनिंग टेबल पेपर रोल मेकिंग मशीन

मटेरियल : Metal

ग्रेड : ऑटोमेटिक

रंग : Black

टाइप करें : अन्य, डाइनिंग टेबल पेपर रोल बनाने की मशीन

कंट्रोल सिस्टम : PLC नियंत्रण

वोल्टेज : वोल्ट (v)

टॉयलेट रोल बनाने की मशीन

मटेरियल : Steel

ग्रेड : ऑटोमेटिक

रंग : Black

टाइप करें : अन्य, टॉयलेट रोल बनाने की मशीन

कंट्रोल सिस्टम : PLC नियंत्रण

वोल्टेज : वोल्ट (v)

|

FEATHER TOUCH TISSUES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें